The Essential Guide to Becoming a High-Impact Manufacturing Assistant: Skills, Roles, and Career Paths

In today’s factories, manufacturing assistants keep things running smooth. They handle key tasks that stop delays and boost output. Gone are the days of pure muscle work; now, these pros blend hands-on help with smart tech to support big supply chains. Think of them as the glue holding production together amid rising demands for speed and precision.

This guide breaks down the skills you need, main duties, education paths, and ways to climb the ladder. Whether you’re starting out or looking to switch roles, you’ll find real steps to land and grow in a manufacturing assistant job.

Core Responsibilities of the Manufacturing Assistant Role

Manufacturing assistants jump into daily tasks that keep production flowing. They support teams by prepping items and watching lines closely. This role demands quick thinking to meet tight deadlines in busy plants.

Daily Operational Support and Workflow Management

You start your shift by gathering materials for the team. Then, you set up parts at workstations so assembly moves fast. Monitoring the production line helps spot jams early.

Time counts here. If a stage lags, you step in to clear it. This keeps the whole process on track, avoiding costly stops. For example, in an auto plant, you’d stage engine parts right before welders need them.

Smooth shifts between steps cut waste. Assistants often use simple checklists to track progress. That way, supervisors see real-time updates.

Quality Control Inspections and Documentation

Spotting flaws early saves headaches later. You do first-piece checks on new runs to confirm specs match plans. Routine scans cover things like bolt tightness or surface scratches.

Tools like calipers or gauges come into play. After inspections, you log findings in systems like MES or ERP software. Accurate records help trace issues back fast.

This work matters a lot. In electronics manufacturing, one missed defect could scrap a whole batch. Strong documentation builds trust with quality teams and meets standards like ISO.

Inventory Tracking and Material Handling

Keeping stock in check prevents shortages. You count items in cycles to match records with reality. Kitting means bundling parts for specific jobs ahead of time.

Safe handling is key. If certified, you drive pallet jacks or forklifts to move loads. Spot low supplies? Alert buyers right away so orders flow.

Picture a busy warehouse: you’d scan barcodes to update inventory apps. This cuts errors and speeds delivery. Good tracking supports just-in-time methods, common in modern factories.

Adherence to Safety Protocols (OSHA Compliance)

Safety comes first every day. You join briefings to learn fresh risks on the floor. Wearing PPE like gloves, helmets, and glasses protects you and others.

Know lockout/tagout rules to shut down machines safely for fixes. See a spill or loose wire? Report it at once to avoid accidents. OSHA guidelines shape all this, with fines for slip-ups.

Training builds habits. In one study, plants with strict safety routines saw 40% fewer incidents. As an assistant, your vigilance keeps the team safe and productive.

Essential Skills for Success in Manufacturing Assistance

To shine as a manufacturing assistant, mix tech know-how with people skills. These abilities help you handle daily challenges and stand out. Let’s look at what sets top performers apart.

Technical Proficiency and Tool Competency

Reading blueprints gives you a clear picture of the build. Basic mechanics help you understand how parts fit. Hands-on with tools—from screwdrivers to drills—builds confidence.

Industry matters too. In aerospace, you might calibrate precision instruments. Auto work could mean using torque wrenches for even bolts. Practice these to work faster and safer.

Start simple. Many learn on sample jobs before live lines. This skill turns new hires into reliable team members quick.

Data Literacy and Digital Tool Navigation

Spreadsheets like Excel track numbers with ease. You input yields or defects to spot trends. MES systems guide your steps with on-screen instructions.

Digital work orders replace paper trails. Get comfy navigating menus to pull reports. This keeps data fresh for managers.

Why bother? Factories rely on numbers now. A quick data check can flag a tool wearing out before it fails. Build this skill to boost your value.

Critical Soft Skills: Communication and Problem-Solving

Clear talk solves issues fast. When a line stalls, you explain it to bosses without fluff. Team chats during shifts build strong bonds.

Troubleshoot small problems solo. Say a feeder jams—you test fixes before calling help. This saves time and shows initiative.

Ever wonder why some assistants advance quick? It’s these skills. They turn routine days into chances to lead and learn.

Educational Pathways and Certification Requirements

You don’t need a fancy degree to start, but the right prep opens doors. Many paths lead to manufacturing assistant roles. Focus on basics that match job needs.

Foundational Educational Requirements

A high school diploma or GED gets you in the door. It shows you can handle math and reading basics. Vocational programs add hands-on classes in shop skills.

Community colleges offer short courses in manufacturing tech. These cover safety and tools in weeks, not years. Graduates often land jobs faster.

Real talk: 70% of entry roles just ask for that diploma. But extra training makes your resume pop.

Industry-Specific Certifications and Training

Lean principles, like Six Sigma basics, teach waste cuts. Yellow Belt certs are quick online or in-class. They prove you think efficient.

Machinery certs match your field—forklift licenses for handling, or CAD intros for design help. Material safety training fits chemical plants.

These boost pay too. Certified assistants earn 10-15% more on average. Pick ones tied to your goals.

On-the-Job Training (OJT) and Apprenticeships

Hired? OJT fills gaps fast. Mentors show real workflows over weeks. You practice under watch till ready.

Apprenticeships blend pay with learning, often two years. They cover advanced tasks like machine setup. Unions or companies run these.

This path works well. Many top techs started as assistants through OJT. It turns book smarts into floor savvy.

Career Progression from Manufacturing Assistant

This role is a launchpad, not a dead end. Gain experience, and doors open wide. See how to move up in manufacturing.

Pathways to Skilled Technician Roles

From assistant, aim for CNC operator spots. Your line knowledge helps program machines right. Quality inspector roles build on your check skills.

Assembler II means leading small teams on complex builds. Foundational work gives context no class can match. In two years, many shift here.

Stats show it: 60% of techs started in support like this. Experience counts big.

Advancing into Leadership and Supervisory Positions

Line lead comes next—you guide shifts and train newbies. Team coordinator handles schedules and morale. Production supervisor oversees whole areas.

Mentor others and suggest fixes to grow. These roles need your floor insight plus people skills. Pay jumps 20-30% with promotion.

It’s rewarding. Supervisors shape how teams work, fixing big issues.

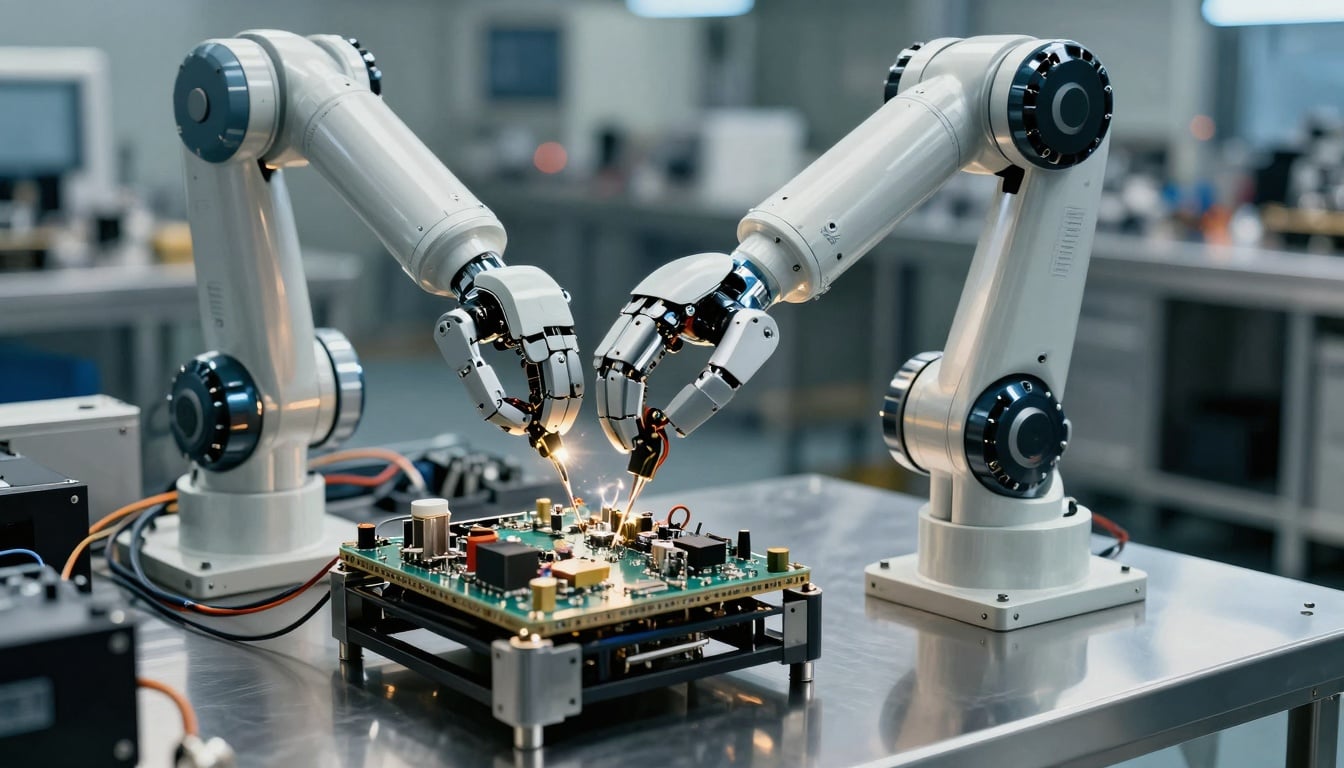

Specialization Opportunities (e.g., Automation Integration)

Dive into robotics support for smart factories. Learn basic coding or sensor checks. Testing gear specialists focus on quality tools.

These niches pay well in growing fields like green manufacturing. Assistants with tech bends excel here. Future-proof your skills this way.

Actionable Tips for Aspiring and Current Manufacturing Assistants

Want to thrive? These steps help you stand out. Apply them daily for real gains.

Tip 1: Proactively Master the Documentation System

Dive deep into your plant’s tracking software. Learn every shortcut and report type. Soon, you’re the go-to for quick fixes.

This builds trust. Bosses notice reliable data entry. It cuts errors and speeds audits.

Tip 2: Embrace Continuous Improvement Methodologies

Join Kaizen sessions to tweak processes. Suggest small changes, like better part layouts. Show you care about the big picture.

Teams value this. It leads to bonuses or nods in reviews. Start with one idea a month.

Tip 3: Cultivate Strong Interdepartmental Relationships

Chat with maintenance folks during breaks. Know supply chain contacts by name. These ties fix problems quicker.

When engineering needs input, you’re ready. Strong networks open promo paths. Build them steady.

Conclusion: Securing Your Future in Manufacturing

Manufacturing assistants face high demand as factories grow. You need tech skills like tool use and data entry, plus soft ones like clear talk and quick fixes. Education starts simple—a diploma plus certs—while on-the-job learning seals it. From there, climb to tech roles, leads, or specialties in automation.

This isn’t just support work; it’s a solid base for lasting growth. Factories need pros like you to stay competitive. Ready to step up? Update your resume today, chase that cert, and hit apply on your next manufacturing assistant opening. Your career boost starts now.